| Brackets for rollercover | A in mm | A in inch | B in mm | B in inch | Z in mm | Z in inch | Z in mm | Z in inch |

| RD 40 | 40 | 1.57 | 60 | 2 | 7 | 0 | 45 | 1 |

| RD 50 | 50 | 1 | 65 | 2 | 7 | 0 | 45 | 1 |

| RD 60 | 60 | 2 | 75 | 2 | 9 | 0 | 60 | 2 |

| RD 70 | 70 | 2 | 85 | 3 | 9 | 0 | 70 | 2 |

| RD 80 | 80 | 3 | 95 | 3 | 9 | 0 | 80 | 3 |

| RD 90 | 90 | 3 | 105 | 4 | 9 | 0 | 90 | 3 |

| RD 100 | 100 | 3 | 115 | 4 | 9 | 0 | 100 | 3 |

| BB - Band width | RB - Roller tuber diameter | AZ - Band travel length |

| Rollercover type | BB in mm | BB in inch | RD in mm | RD in inch | AZ in mm | AZ in inch |

| P&H torsion spring system | 0-200 | 0-7.87 | 21 | 0,83 | 400 | 15,75 |

| P&H torsion spring system | 0-200 | 0-7.87 | 28 | 1,10 | 500 | 19,69 |

| P&H torsion spring system | 0-200 | 0-7.87 | 35 | 1,38 | 800 | 31,50 |

| P&H torsion spring system | 0-200 | 0-7.87 | 40 | 1,57 | 1000 | 39,37 |

| P&H torsion spring system | 201-400 | 7.88-15.75 | 21 | 0.83 | 700 | 27,56 |

| P&H torsion spring system | 201-400 | 7.88-15.75 | 28 | 1,10 | 900 | 35,43 |

| P&H torsion spring system | 201-400 | 7.88-15.75 | 35 | 1,38 | 1100 | 43,31 |

| P&H torsion spring system | 201-400 | 7.88-15.75 | 40 | 1,57 | 1300 | 51,18 |

| P&H torsion spring system | 401-600 | 15.76-23.62 | 21 | 0,83 | 900 | 35,43 |

| P&H torsion spring system | 401-600 | 15.76-23.62 | 28 | 1,10 | 1100 | 43,31 |

| P&H torsion spring system | 401-600 | 15.76-23.62 | 35 | 1,38 | 1300 | 51,18 |

| P&H torsion spring system | 401-600 | 15.76-23.62 | 40 | 1,57 | 1500 | 59,06 |

| P&H torsion spring system | 601-1200 | 23.63-31.50 | 21 | 0,83 | 1000 | 39,37 |

| P&H torsion spring system | 601-1200 | 23.63-31.50 | 28 | 1,10 | 1300 | 51,18 |

| P&H torsion spring system | 601-1200 | 23.63-31.50 | 35 | 1,38 | 1600 | 62,99 |

| P&H torsion spring system | 601-1200 | 23.63-31.50 | 40 | 1,57 | 2000 | 78,74 |

| P&H advanced spring engine | 100-2000 | 3.94-78.74 | 50 | 1,97 | 1500 | 59,06 |

| P&H advanced spring engine | 100-6000 | 3.94-78.74 | 60 | 2,36 | 2000 | 78,74 |

| P&H advanced spring engine | 100-6000 | 3.94-78.74 | 70 | 2,76 | 2500 | 98,43 |

| P&H advanced spring engine | 100-6000 | 3.94-78.74 | 80 | 3,15 | 3000 | 118,11 |

| P&H advanced spring engine | 100-6000 | 3.94-78.74 | 90 | 3,54 | 3500 | 137,80 |

| P&H advanced spring engine | 100-6000 | 3.94-78.74 | 100 | 3,94 | 4000 | 157,48 |

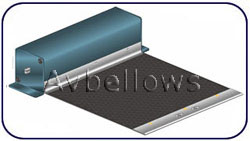

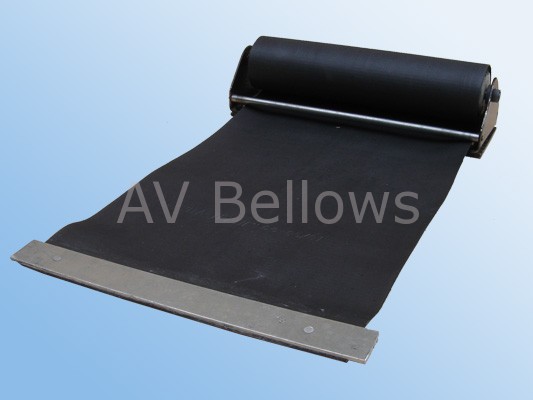

Flexible aprons with rollaway covers

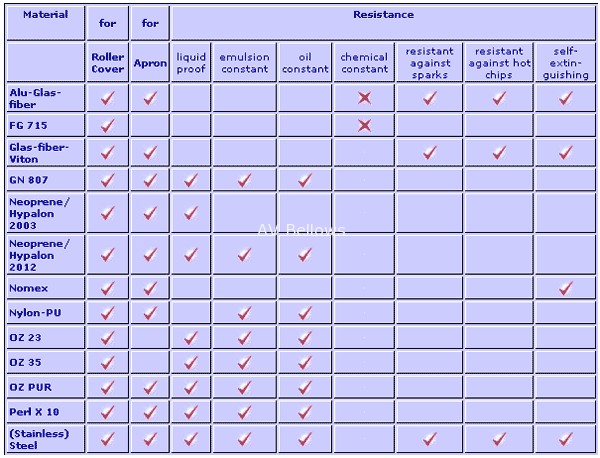

The demand for roller covers with flexible aprons was initiated to protect machines against hot or heavy chips/swarfs. You should give your machine this additional shield protection. The standard roller cover with fabric band cannot be recommended for these applications. The roller covers with flexible aprons don't offer you walk-on capability.

The roller covers with flexible aprons are available in different designs, materials and sizes. If you have limited space we recommend an apron type with curved aluminum links which are riveted to a synthetic fabric with two sided PVC / polyurethane coating or heat resistant aluminum coating. Basically you can also use regular flat brass, steel or aluminum links.

We can even provide you with an all-metal band consisting of aluminum segments. We offer a hollow type and a solid construction. The aluminum links are interlocked with polyurethane hinges providing effective protection against coolants. The low weight of approximately 8 kg/ 17.6 lbs per sqm and the small size makes the product perfect for today's machines.

Flexible aprons (without roller cover)

Basic operating situations available

Our flexible aprons are an easy and inexpensive solution for special applications where only a front protection is required. All products are customized and can be delivered within a short period.

The apron usually consists of a basic fabric structure with riveted link material. The link material can be brass, (stainless) steel or aluminum in flat or curved shapes. The heavy duty type aprons consist of a special hollow aluminum construction. You can choose either a metal to metal connection or a design where the aluminum links are connected with polyurethane hinges offering a coolant resistance.

For easy installation we offer you basically three alternatives; as a simple hanging shield, hanging over a deflection roller or in connection with a roller cover (even with an enclosure). For the deflection roller you can use the same technical details as for the mounting brackets for roller covers (see previous section).

By working together hand-in-hand with our customers and getting their feedback we have been able to develop the roller covers and aprons in the desired direction. We strongly welcome every idea or suggestion from our respected customers and will always support them in their designing process for new machines and new ways of protection.

Rollaway covers with enclosures

Our roller covers with enclosures offer a protection for the roller itself against the working environment, require a minimum of space and can be manufactured customized in different designs.

The enclosure itself can be produced of stainless steel, aluminum, color anodizing or other surface treatments. The standard housing sizes are available from 40 by 40 mm (1.57 * 1.57 Inch) to 120 by 120 mm (4.72 * 4.72 Inch). The enclosure width is not limited. When using stainless steel band the band width can be up to 1.000 mm / 40 Inches. In the case your application requires a fabric band, the width can go up to 6.000 mm / 240 Inches.

Our roller covers with encloser are designed for use in horizontal and vertical positions. Please give us detailed information about the operating position.

All roller covers with encloser are ready to fit into your application. They are factory preadjusted to the necessary forces. Through our special inquiry sheets we will guide you through the design process and make sure that all important information have been considered and included.

Basic dimensions of a roller cover with enclosure: Abbreviations

| GB - Enclosures width | AZ - Extension |

| B - Band width | X - Space required for axis |

Mounting types

Ph : 0422 2395831